Find out just how easy the move towards smart can be

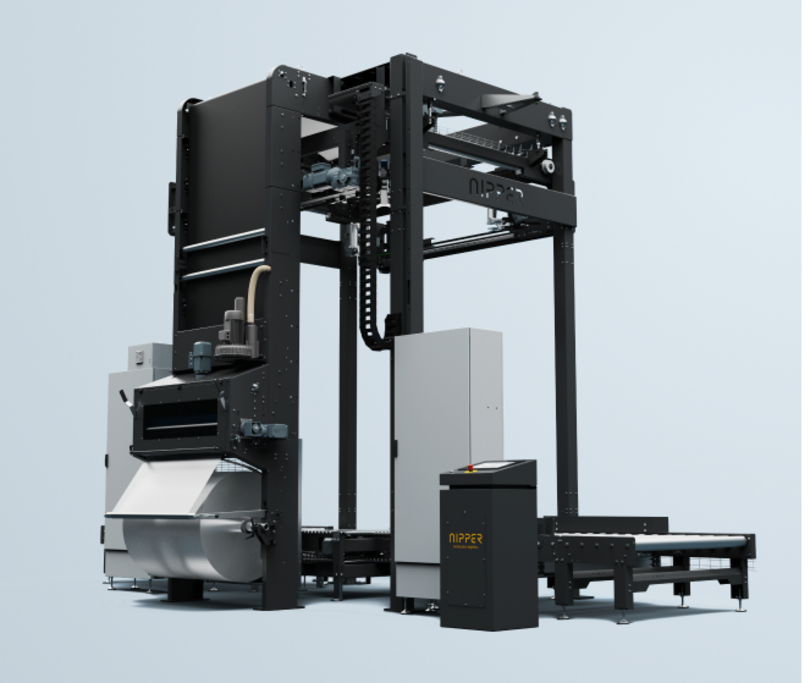

From the Nipper Stretch Hood to the intelligent Nipper AGV, all Nipper’s products have been designed as building blocks. They work seamlessly together with our roller conveyor, pallet elevator, turntable, and traverse systems. And can also easily be integrated into existing logistics processes and plants.

Increased production with fewer people; doesn’t that sound good? With the Nipper AGV, you can deploy your employees where they add most value. The AGV offers 24/7 availability and can replace 5.4 FTE.

The Nipper AGV doesn’t require any special infrastructure, such as inductive wires, magnets, or reflectors. It uses the natural structures in the production environment as reference points for navigation. And it can easily be integrated into your existing business software.

The Nipper AGV can transport a variety of carriers, such as pallets of all kinds of materials, like wood, cardboard, plastic or metal. And wooden and plastic crates, wire mesh containers (metal) and cages.

The contactless Nipper Charging Station fast charges your AGV. The AGV will automatically drive to the charging station if no missions are scheduled or when the battery is empty. When the AGV receives a new mission, the charging process is automatically deactivated.

The Nipper AGV can lift up to 1,200 kilos and its lifting height can be adjusted to a maximum of 238 millimeters. Ensuring the Nipper AGV is perfectly suited for almost any manufacturing company.

To Nipper, our customers are our partners. Based on our years of experience, we can give you excellent advice on the best Nipper solution for your specific production environment. Together, we make the step towards smart an easy one to make.

Request an online DEMO

Learn more about Nipper’s automation solutions

- Gain quick insights into how automating pallet processes with Nipper can streamline your business operations, enhancing efficiency and productivity.

- Explore our solutions in just one hour.

- Have your questions answered directly by our production logistics expert.

- Conveniently connect via MS Teams.

Customer Cases

The future of pallet transport

Easily navigates through narrow spaces

Easily navigates through narrow spaces

We offer the most compact AGV for horizontal pallet transport. Thanks to its omni-directional driving system, the Nipper AGV can move in any direction. Furthermore, this intelligent pallet truck can easily lift pallets up to 1,200 kilos and navigate through narrow spaces.

Meets the most stringent safety requirements

Meets the most stringent safety requirements

Safety is crucial in any manned production environment. The Nipper AGV has been developed to optimally interect with people. Using light signals to communicate with the employees, allowing them to easily determine the status of the AGV and the direction it is driving in. If meets the most stringent safety requirements, such as the ISO 3691-4 safety standards. With the Nipper AGV we have developed a reliable colleague you can count on.

Saves time and money

Saves time and money

When using the Nipper AGV, you save on manpower costs, enjoy 24/7 availability, and realize your ROI within 12 months! We offer a scalable and flexible solution that can be installed quickly and doesn’t need specific infrastructure. And thanks to the training courses we provide, you know how to adjust the settings of the AGV to match the ever-changing production process.

Our building blocks for a smart factory

Request an online demo? SMART move.

After requesting an online demo we will promptly contact you with available demo times and provide a link to our online demo environment.

Why request a demo?

- Gain quick insights into how automating pallet processes with Nipper can streamline your business operations, enhancing efficiency and productivity.

- Explore our solutions in just one hour.

- Have your questions answered directly by our production logistics expert.

- Conveniently connect via MS Teams.

Thank you for requesting an online demo. We will be in touch shortly!

English (EN)

English (EN)

Nederlands (NL)

Nederlands (NL)

Nipper AGV

Nipper AGV

Nipper Stretch Hood

Nipper Stretch Hood